Shining a light on Laser Hallmarking

Published: 16th September 2019

From the early days of hallmarking at the Sheffield Assay Office, hallmarks have been applied by hand using tried and tested methods. Steel punches, jigs and dies are all utilised by our highly skilled marking team to physically stamp the hallmark onto precious metal jewellery. Hand operated presses are also used to enable a fast turnaround for our customers.

Traditionally, articles were supplied in an unfinished state from local craftsmen and could be polished up after the marking process. Now that we hallmark all manner of items originating from all over the globe, this is no longer possible. Laser hallmarking was developed in the late 1990s and removes a tiny portion of metal from the article rather than displacing it. This allows us to mark hollow, thin or highly polished items without fear of bruising, scratching or distortion. Laser marks now account for up to a third of all hallmarks applied in Sheffield.

What is a laser?

A laser is a machine that makes an amplified, single-colour source of light. The laser medium is energized to make it emit light. ... The word "laser" is an acronym for "light amplification by stimulated emission of radiation".

The first working laser was put together and operated in 1960. There are many types of lasers ranging from low energy laser pointers (1 milli-watt) up to high energy cutting and drilling lasers (>10 Kilowatts). There are also a number of different types of lasers CO2, YAG, DPSS and Fibre (to name but a few). The primary laser type currently used for marking or engraving onto metals is the Fibre laser. This recently developed technology simply plugs into standard mains supply, is much more energy efficient, stable and easily transported around site.

How does a laser machine work?

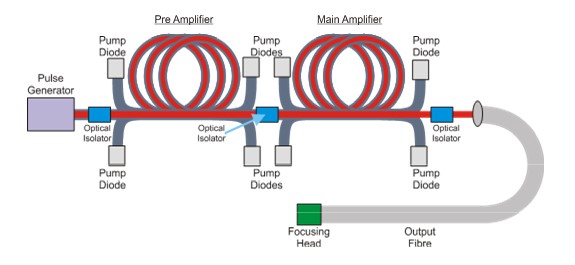

The laser beam is produced from a low power pulse generator (approximately 40 milliWatts) sometimes called a seed laser. The seed laser beam passes through a one-way optical isolator. The optical isolator is used to allow the seed laser out of the pulse generator but prevent the amplified laser beam passing back into the pulse generator and causing damage. The seed laser then passes into the pre-amplifier, which is a section of ‘active’ fibre, about 25 metres in length and is amplified up to approximately one Watt. The one-Watt laser beam then passes through another one-way optical isolator before entering the main amplifier. The main amplifier is also a section of active fibre about 25 metres in length and will amplify the laser beam up to the maximum power.

The pre-amplifier and main amplifier consist of one or more pump fibre optics and an Ytterbium (Yb) doped active fibre optic. The fibres are all spliced together at or around the optical isolators. The pump fibres are connected to numerous pump diodes. The power from the pump diodes passes from the pump fibre into the lasing fibre. When in the lasing fibre, the Ytterbium will absorb this power to ‘excite’ the Ytterbium atoms. A photon of the correct wavelength (colour) travelling along the excited fibre will stimulate the emission of other photons and so the laser amplification process takes place.

The laser light emitted from the main amplifier then passes through another optical isolator (to prevent damage occurring to the preamplifier) and enters the output fibre

The laser light is emitted from the output fibre in a large cone which is collected and made parallel (collimated) with a lens in the output housing. The output housing also contains a final anti-back reflection device to prevent light reflected from the part being marked getting back into the laser. This minimizes the risk of damage inside the laser.

The result is a highly focused narrow beam of light which will vaporise the target metal with precision to enable complex marking of very small components of jewellery.

The use of Lasers in Hallmarking

There are two distinct types of laser hallmark, and each has its benefits.

A skeletal or outline mark is often useful in for hollow, semi-finished or intricate jewellery products where a punch mark would damage the item. It is a quick process, and only removes a slight layer of the metal from the article.

A deep relief or 3D mark is used to apply larger marks on finished or semi- finished products particularly where a display or feature mark is required. The process removes several layers of metal from the article, and as a result it resembles a traditional struck mark. It is longer lasting and retains excellent definition when polished. These marks can be seen on a number of items such as key-rings, photo frames or silver giftware.

If you are unsure which type of hallmark you need for your specific requirements, our team of experienced technicians are on hand to give advice.

Other applications:

Our laser technology is also ideally suited for clearly and accurately marking a range of logos, signatures and serial numbers for decorative, promotional or engineering and industrial purposes. For one-offs and prototypes, this allows small quantities to be produced without the need for expensive tooling. For volume production, we can use jigs and semi-automation to speed up the process. We accept drawings via email in popular formats such as: dxf, dwg ai, cdr, jpeg, bitmap or pdf and have expertise in the transfer of design from scanned image to computer graphic that can be programmed into the laser machines.

Popular uses include logos, serial numbers, dates, stone weights and personalisation of jewellery.

The Sheffield Assay Office was established in 1773, under an Act of Parliament and today the company assays and hallmarks the precious metals - silver, gold, platinum and palladium. Sheffield Assay Office is one of only four UK assay offices who all work to uphold the Hallmarking Act of 1973 and continue to ensure consumer protection for customers purchasing precious metals.

To find out more about the whole range of services offered by Sheffield Assay Office, such as our hallmarking and analytical services, please email us at info@assayoffice.co.uk or complete the contact form on our website at http://www.assayoffice.co.uk/contact-us ,

Sign up here to all the latest news from Sheffield Assay Office direct to your inbox