The Antimicrobial Properties, and Uses, of Copper

Published: 22nd October 2020

Copper was the first metal to be worked by people and was used mainly in production of coins, along with silver and gold. Nowadays the most common use is in electrical equipment such as wiring and motors. This is because it conducts both heat and electricity very well, and can be drawn into wires.

Recently, the antimicrobial property of copper alloys is taking great popularity. Extensive research is starting to show positive results how copper, brass and bronze are capable of killing harmful, potentially deadly bacteria. Copper’s potential antimicrobial properties could be used as self- sanitizing materials to complement infection control strategies especially on surfaces.

The essentiality of copper lies in its ability to undergo redox reaction between the oxidized forms Cu (II) and reduced one Cu (I) and consequently the damage caused to cell membranes of bacteria and viruses.

The chemical requirements for copper alloys can vary depending on material source and final application. There are different analytical techniques to determine the composition of copper compounds. Analytical Services can offer a wide range of test methods to confirm these specifications.

There are several different analytical techniques that can be used to determine the composition of copper and its alloys.

Analytical Services can offer four different techniques; each technique can be run individually and/or the application of some of them together can give a detailed chemical composition of material to be analysed. The selection of one technique over another is associated with application of the copper alloy.

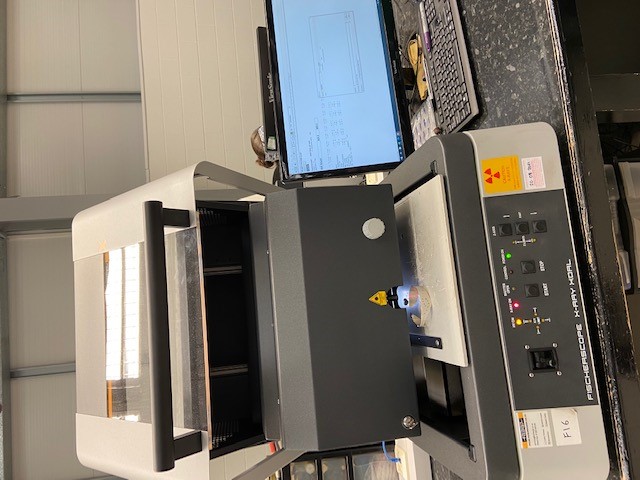

X-Ray fluorescence (Energy Disperse), XRF-ED.

-

This analytical technique is non-destructive and focuses the testing on the sample surface. For this, it’s very useful for evaluating surface contamination, coating composition and contents of major “heavy” elements, which are in the middle of the period table of elements. The testing can take only a few seconds when well calibrated equipment and experience chemist conducts the testing. Contrarily, XRF-ED cannot include the contents of low atomic number elements such as gases, aluminium, sodium, silicon, magnesium, etc.

XRF is well applied for in the copper recycling industry to estimate the copper and the impurities from other elements present. We conduct the testing by XRF on a copper button which has been previously sampling and melt at our facilities.

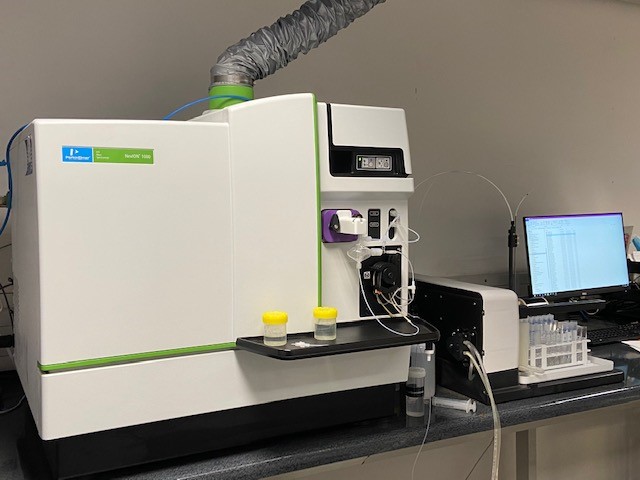

Inductive Couple Plasma- Optical Emission Spectrometry, ICP-OES

- This technique is applied to material/samples in liquid phase, therefore copper based samples must be extracted fully with an acid mixture prior to analysis by ICP-OES. Once sample/s are in solution, they are disintegrated in elemental wavelengths under a plasma source to determine their composition. ICP-OES can determine elemental contents from high percentage ~100% to 0.0005%. This technique is extremely flexible, requires good understanding of chemistry and comprehensive service maintenance internally and externally.

- ICP-OES is the most popular technique for copper samples analysed in Analytical Services. The analysis is under ISO 17025:2017 (UKAS) accreditation.

Inductive Couple Plasma- Mass Spectrometry, ICP-MS

- This technique is similar to ICP-OES in the dissociation source (plasma) but the elemental differentiation is based on the elemental masses. ICP-MS is used to determine content from low part per millions to parts per billions. Both ICP techniques can complement each other when sample matrices can affect the content determination for particular elements. ICP-MS is used for very high grade copper 99.99% and any potential contaminant must be measured to 0.0001%.

Gases analyser for carbon, sulphur, oxygen, nitrogen and hydrogen

- For copper based material, carbon and oxygen are generally the elements to be tested. Carbon content is determined by combusting the sample under oxygen flow to produce CO2 which is measured by infra-red cells and the intensities compared with a calibration. From oxygen determination a sample is fused in a graphite crucible in an electrode furnace, using helium as a carrier gas and oxygen is converted to CO2 and measured by infrared absorption. For the testing of gases is important to avoid any contamination from the environment if sample is heat during preparation, casting process, etc. Equipment capability and cleanness are key parameters to achieve good detection of limits, which are one of the main requirements for copper materials.

.jpg)

The Sheffield Assay Office was established in 1773, under an Act of Parliament and today the company assays and hallmarks the precious metals - silver, gold, platinum and palladium. Sheffield Assay Office is one of only four UK assay offices who all work to uphold the Hallmarking Act of 1973 and continue to ensure consumer protection for customers purchasing precious metals.

To find out more about the whole range of services offered by Sheffield Assay Office, such as our hallmarking and analytical services, please email us at info@assayoffice.co.uk or complete the contact form on our website at http://www.assayoffice.co.uk/contact-us ,

Sign up here to all the latest news from Sheffield Assay Office direct to your inbox